Important Information

In sandy loam, the approximate amount of lime required to raise the pH of your ground to a depth of 600mm (2ft) by one pH unit (eg. to go from 6.5 to 7.5) would be 1.5 to 2.0 tonnes per hectare.

In heavier clay soils, you will probably need at least twice as much lime to raise the pH level by one unit.

Lime is relatively inexpensive and used effectively, your investment will bring excellent returns over many years.

Agricultural Lime

Lime has been proven to increase farm profits and sustainability by decreasing soil degradation. Agricultural lime has always been a stalwart of fertilisers and soil conditioning products. Long known for its ability to reduce soil acidity (increase Ph) and repair non-wetting soils. It is only now coming into view that the type of lime used, whether it be lime sand, lime stone or coral lime, can make a sizeable difference in the speed and efficacy of the limes effect on the soil.

Western Agriculture Lime Company

Most current testing of lime quality involves discovering the neutralising value of the lime based on method P33, which uses hydrochloric acid to react with the Calcium Carbonate neutralising the acid. The more acid that can be neutralised by a determined sample of the lime product the higher the Calcium carbonate content of the lime. Fortunately your soil is nowhere near the acidity of Hydrochloric acid. If it was then you would need a lot of lime in order to grow anything.

Another lesser known test is the Hars/Resin test, which uses an acid with a pH value close to the average pH value of soil to give you a more accurate indication of how much of the product is going to be readily available and how much is going to need a good amount of time for the soil to slowly break it down. Much like the ocean breaks away at the limestone cliffs of our coastline except without the pounding action of millions of tones of seawater everyday.

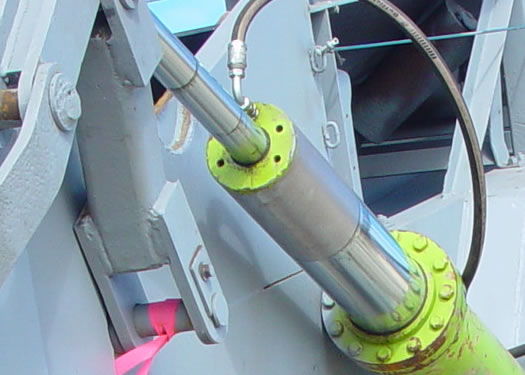

Wet versus Dry Particle Size Analysis

The analysis of particle size distributions has become increasingly important in industrial and agricultural processes. Particle size is recognized to be fundamental to the control of operations as diverse as grinding, crystallization, emulsification, agglomeration, and more. Particle size determination has traditionally been relegated to the laboratory, and is performed by slow, labour-intensive methods such as sieving, sedimentation columns, and the like.

Applications

Applications of the wet sieving apparatus are the fields of agriculture and land conservation (research on soil erosion, land degradation/ conservation, salinization, agriculture, sustainable agriculture). Determining aggregate stability will give information on the sensitivity of soils to water and wind erosion, which might be prevented e.g. by mulching the soil surface. Information on soil aggregate stability can also improve tillage programs, adapted to the specific soil type and crop demands.

What is Wet Sieving?

Wet sieving is a procedure used to evaluate particle size distribution or gradation of a granular material. It’s also used to prepare a granular material for particle size analysis by removing fines that may impede the separation process.

Materials and Applications

Wet sieving is an ideal sample preparation process for specimens with a high fraction of granular materials and enough fines content present to make sieving difficult. The fines can stick together in clumps, preventing an accurate assessment by sieving. Wet sieving is also useful for direct particle sizing of problem materials including:

- Soils and mineral aggregates with high fine contents

- Agricultural soil with a high clay content

- Clay suspensions

- River sediments

- Contaminated soil (brownfields)

- Materials that are fragile but not soluble, such as coal or other minerals

- Lightweight powders

- Sludge and glazes

- Kaolin and fillers

- Abrasives

- Micro granulations

How Do the Testing Procedures Work?

Wet sieving is usually performed with one of two purposes in mind. Either the operation is performed to determine a fraction retained on a sieve or sieves, or it is a method of sample preparation that allows a later particle size analysis to be performed more easily or accurately.

It’s important to be aware that any wet sieving method has the potential for sample loss during the process. Some material may be washed away during agitation or decanting or may be forced into crevices of the sieve and become trapped. The percentage loss is very small and the accuracy and efficiency of wet sieving compared to dry sieving is worth the process if necessary for your application.

A sieve analysis (or gradation test) is a practice or procedure used to assess the particle size distribution (also called gradation) of a granular material by allowing the material to pass through a series of sieves of progressively smaller mesh size and weighing the amount of material that is stopped by each sieve as a fraction of the whole mass.

The size distribution is often of critical importance to the way the material performs in use. A sieve analysis can be performed on any type of non-organic or organic granular materials including sands, crushed rock, clays, granite, feldspars, coal, soil, a wide range of manufactured powders, grain and seeds, down to a minimum size depending on the exact method. Being such a simple technique of particle sizing, it is probably the most common.

Limitations of sieve analysis

Sieve analysis has, in general, been used for decades to monitor material quality based on particle size. For coarse material, sizes that range down to #100 mesh (150μm), a sieve analysis and particle size distribution is accurate and consistent.

However, for material that is finer than 100 mesh, dry sieving can be significantly less accurate. This is because the mechanical energy required to make particles pass through an opening and the surface attraction effects between the particles themselves and between particles and the screen increase as the particle size decreases. Suspending the particles in a suitable liquid transports fine material through the sieve much more efficiently than shaking the dry material.

Sieve analysis assumes that all particle will be round (spherical) or nearly so and will pass through the square openings when the particle diameter is less than the size of the square opening in the screen. For elongated and flat particles a sieve analysis will not yield reliable mass-based results, as the particle size reported will assume that the particles are spherical, where in fact an elongated particle might pass through the screen end-on, but would be prevented from doing so if it presented itself side-on.

Properties

Gradation affects many properties of an aggregate. It affects bulk density, physical stability and permeability. With careful selection of the gradation, it is possible to achieve high bulk density, high physical stability, and low permeability. This is important because in pavement design, a workable, stable mix with resistance to water is important. With an open gradation, the bulk density is relatively low, due to the lack of fine particles, the physical stability is moderate, and the permeability is quite high.

Methods Of Sieve Size Analysis

Wet Sieving Sieve analysis is a simple but proven method of separating bulk materials of all kinds into size fractions and to ascertain the particle size and distribution through weighing the single fractions. Usually, sieving processes are carried out on dry material. However, when dry sieving cannot produce an adequate degree of separation between the individual fractions and even sieving aids cannot improve the quality, wet sieving is called for.

ISO 20977:2018-Liming materials – Determination of size distribution by dry and wet sieving. The dry sieving of powdered material containing individual particles can be carried out quite easily. This simple, quick and cheap method enables the determination of the particle size of water-soluble materials. Therefore, the dry sieving method should always be used first. However, the sieve apertures can become blocked by sample particles, a phenomenon known as blinding. Blinding is mainly caused by caking and the production of electrostatic charges, particularly on sieves with small apertures.

Dry sieving of very wet material can also lead to blinding. These difficulties are not encountered with the wet sieving method, which is applicable to any kind of material such as powders (dry or wet), paste-like products or granules except those containing water-soluble constituents. In order to ensure the comparability of results, all masses of size fractions are expressed as dry matter.

| Method A - the dry sieving method | Method B - the wet sieving method |

|

|

Manypeaks

Homestead Road

Manypeaks WA 6328

Ph: (08) 9846 1308

Freecall: 1800 803 003

Windy Harbour

Salmon Beach Road

Windy Harbour WA

Ph: (08) 9776 1206

Freecall: 1800 803 003

Benefits of Agricultural Lime

Lime has been proven to increase farm profits and sustainability by decreasing soil degradation. Agricultural lime has always been a stalwart of fertilisers and soil conditioning products. Long known for its ability to reduce soil acidity (increase pH) and repair non-wetting soils. It is only now coming into view that the type of lime used, whether it be lime sand, lime stone or coral lime, can make a sizeable difference in the speed and efficacy of its effect on the soil.

The three basic types of Agricultural lime can be loosely classified as follows:

Lime Sand

- Lime sand is a lime product that needs very little processing due to its already fine nature. However as a sand it is still not highly soluble as can be seen by placing a little of the lime sand in a glass of water, mixing it up and waiting for it to settle to see how much of the substance has actually dissolved into the solution of water, and the depth of the fine layer that settles to the top of sample.

Chalk lime

- Chalk lime is a very loose way to describe the lime in question as it is not completely chalk and often contains small pockets of limestone and lime clays. The deposit is blended to produce a lime product with a high Calcium Carbonate content and is also highly soluble, in part owing to the existence of pockets of pure Calcium Carbonate (the chalk bit) which when crushed and screened is almost instantly dissolved into water. The chalk lime as a whole is readily dissolved by standard drinking water and as such yields the fastest and biggest results in terms of conditioning soil.

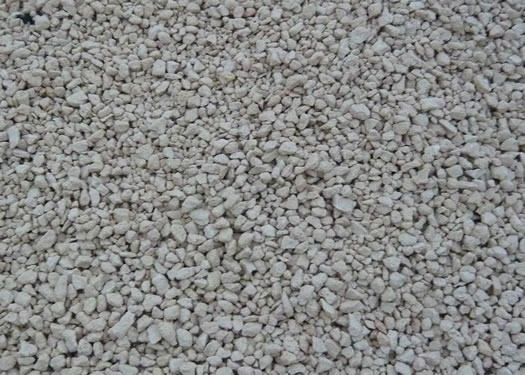

Limestone

- Limestone is as suggests Calcium Carbonate in rock form and as such is very hard and takes time to dissolve and be usable in the soil. The crushed lime stone product sold for use as a soil conditioning product is very high in Calcium Carbonate but due to its hardness will take time to produce results.

The chalk lime we produce at our quarry on Homestead Road Manypeaks has often been described as a clay lime. This is in part true as clay can be described as “a naturally occurring material composed primarily of fine grained minerals, which is generally plastic at appropriate water contents”. Thus the ability of our product to be soluble enough to form a clay like substance after the application of a small amount of water shows it’s superiority in how quick your soil will have access to the Calcium Carbonate in the product.

By improving the balance of critical nutrients and moderating soil acidity, natural lime fertiliser ensures that your yields will be not only bigger, but will be qualitatively improved as well. Crops will taste better and feed produced from these crops will result in healthier livestock.

Benefits

The following are a few of the benefits you will gain by adding agricultural lime to acidic soils.

- Calcium is an important constituent of cell wall material, adding strength and stability to the plant. Calcium deficiency causes stunted growth .

- Lime corrects acidification. Soil acidification is part of Australia's land degradation problem. As far back as 1989, the CSIRO estimated that soil acidification was costing Australia more than $300 million per year in reduced crop production.

- Adequate levels of lime in the soil will reduce Aluminium and Manganese toxicities. The lower the soil pH, the more readily these toxic elements are released into the soil to adversely affect the health of growing plants.

- Fertiliser efficiency is improved when agricultural lime is added to acid soils. Liming acid soils will increase the uptake of nitrogen, phosphate, potash, sulphur, calcium, magnesium, boron, copper, zinc and molybdenum.

- Beneficial soil bacteria are generally more prevalent in the sweet alkaline soils rather than acid soils.

- Agricultural lime improves soil structure and promotes worm activity. The addition of lime to most soils will improve their friability, thus reducing crusting and clodding of heavy soils.

- The composting of organic matter in the soil is significantly improved, thus contributing to good soil composition and less need for ongoing tillage.

- Reduces the need for costly and potentially toxic chemical fertilisers and completes an eco-friendly and environmentally sustainable approach, and complies with all requirements for ‘organic’ labeling.

Note

In sandy loam, the approximate amount of lime required to raise the pH of your ground to a depth of 600mm (2ft) by one pH unit (eg. to go from 6.5 to 7.5) would be 1.5 to 2.0 tonnes per hectare.

In heavier clay soils, you will probably need at least twice as much lime to raise the pH level by one unit.

Lime is relatively inexpensive and used effectively, your investment will bring excellent returns over many years.

The above information should only be used as a guide and for the best results we recommend the testing of your soil and the matching of those tests to the particular crop you wish to cultivate.

CALpHOMIN

CALpHOMIN is a new broadacre product that WALCO is producing to re-energise soils, to enable them to use more of the minerals already in the soil, to encourage the growth of beneficial life in the soil and increase resistance to frosts and blight.

Limestone Rubble

We currently have 2 grades of limestone rubble available;

- 10mm to 25 mm

- 50mm to 10mm

Limestone Rock

Limestone cap rock sourced from Windy Harbour is a very hard wearing stone compared to other limestone products. The method of extraction produces a hard stone resource varying in size from rubble to the size of a small car.

- Due to its hard wearing properties this stone is perfect for building;

- It creates a beautiful contrast with the surrounding environment;

- It enhances any other materials used in the construction of a building or retaining wall.

Ag Lime

Our primary source for Ag lime is our Manypeaks pit located 40mins east, north east of Albany.

- Our Manypeaks lime is a chalk lime which makes it highly soluble and very readily absorbed;

- It is a very effective wetting agent for non wetting soils, replacing the bonds that are destroyed by acid sulphate soils;

- This chalk lime is a rare product and the solubility of the fines is not able to be replicated in other Ag Lime products, therefore you will rarely see chalk lime used as a comparison against lime sands;

- Although the lime sands quite often have a higher Calcium Carbonate content than the blended chalk lime product, logic dictates that sand will never be as readily absorbed into the soil as a softer chalk/clay product.

We also source lime from our Windy Harbour pit.

- Due to it being solid limestone rock, and not a sand or clay based product, this lime is very high in Calcium Carbonate (the active ingredient in agricultural lime).

| PRODUCT PRICE LIST | |||

|

Ag Lime - Manypeaks quarry |

$31 p/tonne + GST | Ag Lime - Windy Harbour quarry | $27 p/tonne + GST |

| Limestone Rubble |

$30 p/tonne + GST | Building Stone | $30 p/tonne + GST |

| Magnesite | $40 p/tonne + GST | CALpHOMIN | $100 p/tonne + GST |